Sustainability and environmental responsibility are a part of how we do business

While Apogee’s products and services help our customers achieve their green building and sustainable design goals, our commitment to sustainability extends to our own operations as well. Across our businesses we work hard to incorporate sustainable practices into all aspects of our operations. We maintain a relentless focus on eliminating waste and minimizing resource consumption. Our Apogee Management System is a central part of Apogee’s culture and is a key component of the way we do business.

Environmentally Responsible Operations

We believe that protecting the environment and conserving resources are the right things to do. As a leader in our industry, we are committed to environmentally sustainable manufacturing practices.

Apogee’s Environmental Policy

It is the Company’s policy to comply with all applicable environmental laws and regulations and to conduct its business in a manner that protects the environment, Company employees, stakeholders, and our customers. Our complete enterprise-wide environmental, health and safety policy and additional corporate governance documents are available on the Corporate Governance page in the Investors section of our website.

Examples of our commitment to environmentally responsible operations include:

Energy efficient lighting

- Most of our manufacturing facilities have switched to energy efficient LED lighting, which has improved lighting levels while significantly reducing energy consumption.

- For example, our Wausau fabrication facility upgraded 772 florescent lights to LED on it production floor, leading to a nearly 20% reduction in electricity costs.

- Similar lighting upgrades have recently been completed in other Apogee business units, including Linetec, Tru Vue, Viracon, and Harmon.

Recycling and waste reduction

- Apogee has recycling and waste reduction programs in place across our locations which divert hundreds of tons of materials from the waste stream each year.

- We recycle numerous types of materials, including: aluminum scrap, glass scrap, packaging, crating materials and cardboard, paper waste, solvent, and waste oil.

Environmentally friendly paint operations

- Our Architectural Framing Systems business employs the latest Regenerative Thermal Oxidizer technology which protects the environment by capturing and destroying the VOCs present in liquid solvent-based paints.

- We have voluntarily eliminated the use of paints containing lead, mercury, and cadium.

- We continually seek innovative ways to reduce paint consumption and waste. Our Linetec business unit has reduced paint usage and waste by more than 20% over the past five years and nearly 100% of paint-related waste is safely eliminated so it does not end up in landfills.

Reusable shipping containers

- Partnering with our customers, several of our business units utilize reusable bunks, containers and cradles for shipping raw and finished products.

- These containers can be used for many years and are designed to efficiently use the space within a truck or trailer, while eliminating the waste from disposable packaging material and wood pallets.

- In addition to reusable shipping containers, several of the business units reuse crating lumber and packaging materials in outbound shipments, effectively upcycling these products.

LEED Certified Facilities

While Apogee supports green building projects and sustainable design goals for our customers, we also operate our own LEED certified facilities.

Our Wausau fabrication facility is LEED Silver Certified, incorporating numerous environmentally friendly design features and construction practices.

Apogee’s corporate office in Minneapolis was designed to be environmentally sustainable and achieved a LEED for Commercial Interiors (LEED-CI) Silver rating. Several Apogee products were incorporated into the building and office space. The building is enclosed with Viracon floor-to-ceiling energy efficient glass. Viracon silk-screened glass was used to enclose offices and conference rooms, while Tubelite's recycled aluminum metal systems, with eco-friendly finishes from Linetec, were used to frame conference rooms and doors. Additionally, Wausau light shelves are used to redirect sunlight into interior offices.

Our Impact

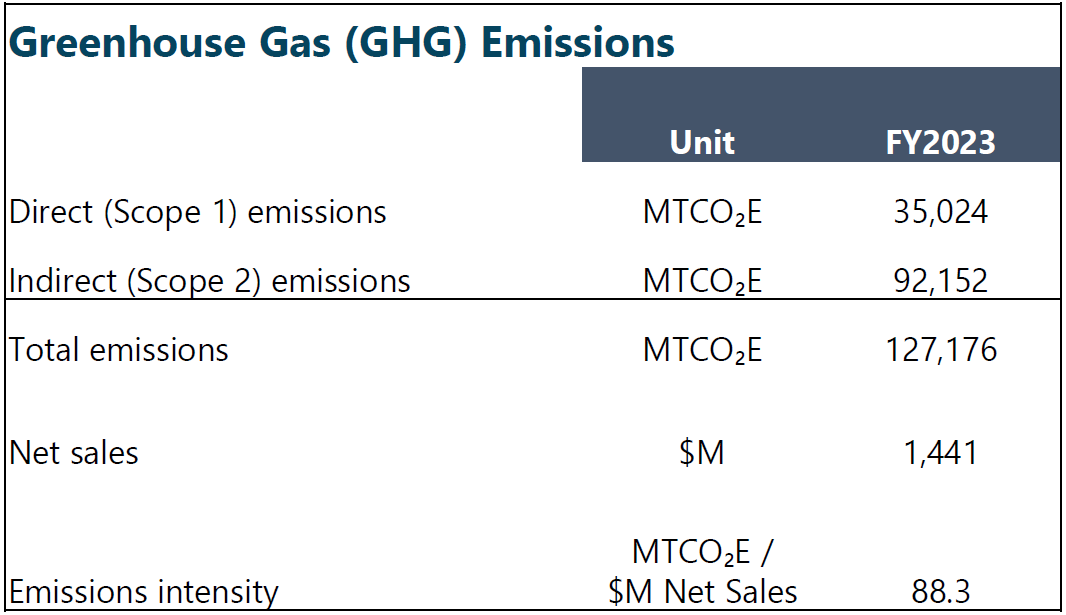

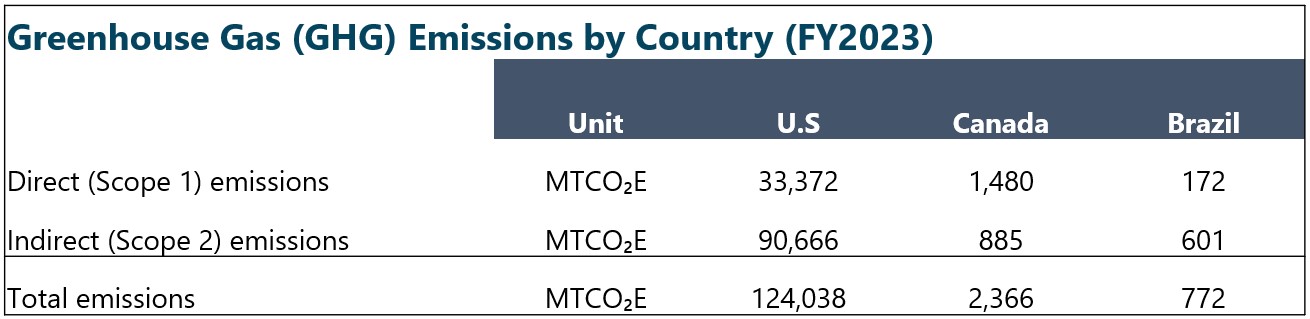

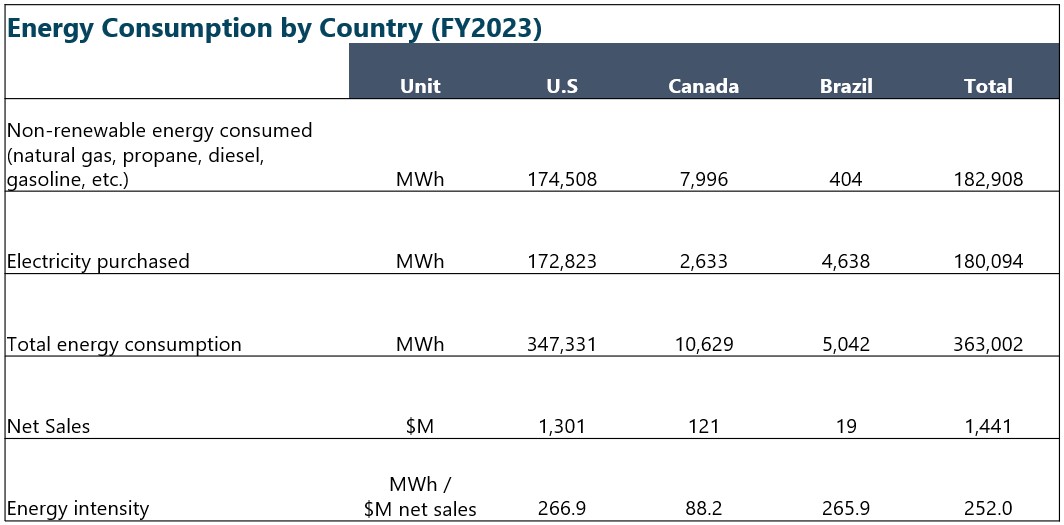

Greenhouse Gas (GHG) Emissions & Energy Use

For the fiscal year ending in February 2023, we collected data on our greenhouse gas (GHG) emissions and energy use for the first time, establishing this as our baseline year. We will use this data to evaluate opportunities for reducing our emissions and energy use in the coming years.

- MTCO₂E is metric tons of carbon dioxide equivalents.

- Scope 1 emissions include fossil fuels consumed in our operations, primarily natural gas, propane, and motor fuels.

- Scope 2 emissions include purchased electricity.

- 100% of electricity purchased is from the grid.

- Energy metrics are based on metered data and estimates of fuel consumed on-site at company owned and leased facilities and in company-operated vehicles.

Waste Recycling

Apogee has recycling and waste reduction programs in place across our locations which divert hundreds of tons of materials from the waste stream each year. These programs align with our environmental and lean manufacturing strategies.

We recycle numerous types of materials, including aluminum scrap, glass scrap, packaging, crating materials and cardboard, paper waste, solvent, and waste oil.

The primary raw materials we use in our products are aluminum and glass. In fiscal year 2023, we recycled 28 million pounds of aluminum scrap across our business operations. Approximately 75 percent of this aluminum scrap was reused in our operations to manufacture products with recycled aluminum content, The remainder was recycled and sold to scrap buyers. On average, we recycle over 40 million pounds of glass scrap, known as cullet, each year. Some of this recycled cullet is sold back to our primary glass suppliers to reuse in their operations. The remainder is sold for use in applications such as fiberglass, road paint, and sand blasting material.

In addition to our own recycling efforts, our aluminum and glass products are fully recyclable at the end of their useful lives.

Apogee Management System

The Apogee Management System, or AMS, is a framework that provides resources to support a culture of excellence in all aspects of our business. AMS is built on the foundation of Lean Principles and Continuous Improvement. Through AMS and Lean, we have a relentless focus on eliminating waste and minimizing resource consumption across our organization. Our efforts are customer focused and data driven, with the goals of improving productivity, and adding value for customers. While AMS is primarily focused on improving business results, it creates a culture that emphasizes continuous improvement, employee empowerment, respect for the individual, and waste minimization.

Responsible Supply Chain

We are committed to conducting business in an ethical and responsible manner and we expect our suppliers to do the same. We have developed a Supplier Code of Conduct to establish our expectations for suppliers.

Conflict Minerals

Apogee is committed to conducting our business with the highest ethical practices, and we are committed to complying with the U.S. Securities and Exchange Commission rule requiring companies to disclose their use of gold, tin and other "conflict minerals" from the Democratic Republic of the Congo and adjoining countries.

Email conflictminerals@apog.com with questions or to report any concerns regarding the circumstances of mineral extraction, trade, handling and export in a conflict-affected and high-risk area.

Resources

Supplier Resources

- An Introduction to Conflict Minerals – English

- An Introduction to Conflict Minerals – Spanish

- RMI Supplier Training Module 1-Introduction to Conflict Minerals Requirements

- RMI Supplier Training Module 2-Supplier Surveys

- RMI Supplier Training Module 3-Risk Assessment

- RMI Supplier Training Module 4-Conflict Minerals Policy